FAQ: What are Terminal Pins?

Form Cut regularly receives questions about terminal pins. In this FAQ, we address some of the more common questions we hear.

Q: What are terminal pins?

Used to form electrical connections, terminal pins are also commonly referred to as lead pins, connectors, feedthroughs, and terminal ends – but whatever their name, they all serve the same purpose.

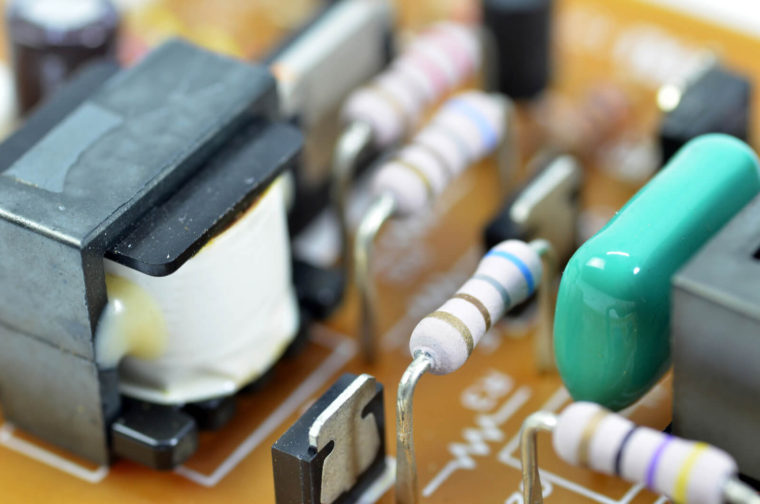

Once manufactured, terminal pins are incorporated into a completed assembly, such as pin headers, hermetic seals, edge connectors, female sockets, printed circuit boards, etc.

A circuit board with pin assemblies.

Q: Does Form Cut manufacture the entire pin assembly?

No, we manufacture only the pins.

By focusing on pins only, we’re able to provide a wide range of pin shapes and forms, including U-bends, C-bends, hooks, and other shapes, in sizes ranging from 0.003” diameter to 2” wide.

Q: Does a standard configuration for terminal pins exist? Meaning, can I order “off the shelf” terminal pins?

We make all terminal pins to customer specification based on the application and end use – nothing is pre-made or “off the shelf.”

Since all pins are made-to-order, no standard configuration exists. Terminal pins can have flattened ends or nail heads, come with flanges or have S shapes, and feature U-bends, C-bends or “crank” bends.

In the image below, the yellow bent pin features a flattened end with cut-out, which allows the metal contact to be swaged into the hole. The flattened section in the middle of the pin keeps it from turning in or being pulled from the plastic substrate into which it’s inserted.

For another customer, we created C-bend copper pins. The round wire was flattened at one end and squeezed to 0.015 of an inch. The flattened end was then bent into a “C” shape, which creates a platform onto which engineers can solder a connection.

Q: Of what materials are terminal pins manufactured?

Material is based on the end use and customer specification. Customers have requested materials ranging from copper alloy to Kovar® with gold-on-nickel plating.

Form Cut works with all formable metals, including 52 Alloy, nickel and nickel alloys, and all grades of stainless steel. Be sure to view our Materials page for a complete list.

We can also recommend materials based on your specific end use – or recommend a material to save on costs.

Q: Can you help us reduce terminal pin production costs?

Yes, absolutely! Once we see your drawing and material specs, and understand the application, we can suggest ways to reduce process steps or production costs.

When contacting Form Cut about your terminal or connector pin application, please let us know as much as possible:

- Where and how the part is being used

- Material needed

- Manufacturing process (e.g. how the part will be assembled)

- CAD drawing or photo / dimensions

- Price you’re currently paying or budget

- Etc.

Our engineers can help you tweak designs, recommend process improvements or help you choose materials that cost less but still meet specifications.